Whip Mix - Replacement Parts Vac-U-Mixer

Product Information:

- Products Model: 09091

- Product Brand: Whip Mix

- Condition: New

- Warranty: Satisfaction Guaranteed

Product images shown are for illustration purposes only and may not be an exact representation of the product. If you have questions regarding product images click here. The shipping cost provided is an estimate. Actual shipping and handling costs may vary based on the destination, logistics, supply chain challenges, and other shipment requirements. The actual shipping cost will be added to the final invoice.

#6375 Slotted Drive Nut - for operation w/ COMBO UNIT or POWER MIXERS - R.H. Thread

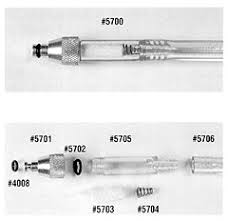

Drive Nuts and Chucks

Whip Mix driving motors provide two basic speeds. High speed at 1725 rpm is recommended only for vacuum-investing with the 200 mL or 300 mL VAC-U-SPAT. Because of its small paddle diameter, the VAC-U-SPATgives the most uniform results with all inlay investments with high speed spatulation.

Low speed at 425 rpm is recommended for all VAC-U-MIXERS when spatulating gypsum materials, alginates and large quantities of investments. The POWER-MIXER with Vacuum provides only low speed. But the COMBINATION UNIThas two drive speeds: the rear Drive Chuck #6108 is the high speed at 1725 rpm, and front is the low speed at 425 rpm. Drive Nuts on the mixing units and corresponding drive chucks on motors have been designed to prevent the interchange of a mixing unit between these two speeds.

Also, the directions of rotation of the drive chucks for these speeds is opposite. The high speed drive chucks of the discontinued VAC-U-VESTOR and the COMBINATION UNIT require a Left-Hand thread for the paddle shaft and drive nut. The low speed drives of the COMBINATION UNIT, and the POWERMIXERwith Vacuum, need a Right-Hand thread for the paddle shaft and drive nut.

It is important, therefore, that the proper drive nut is specified whenever a mixing unit is ordered. And when adapting a mixer already in use the thread direction must be considered — sometimes the entire paddle assembly must be changed.

€‹